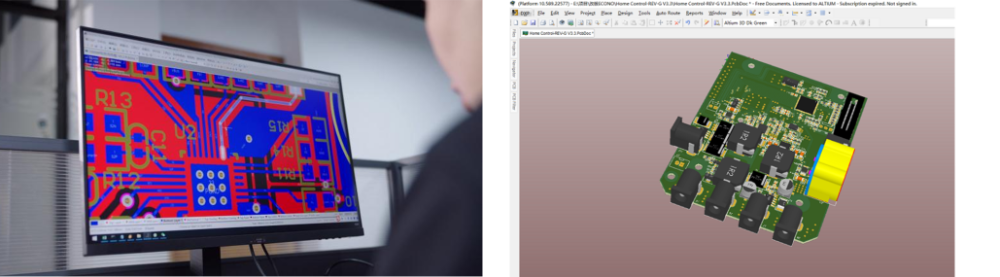

PCBA design and manufacturing is a critical phase in the development of electronic products. It involves the meticulous process of designing the layout of the printed circuit board, selecting the right components, and planning for efficient assembly.

We take pride in offering top-notch PCBA (Printed Circuit Board Assembly) design and planning services to meet the diverse needs of our customers. Our comprehensive approach to PCBA design and planning ensures that your specific requirements are met with precision and expertise.

Yiteng SMT workshop is equipped with two complete surface mount technology assembly lines including Automatic PCB loader, imported printers high Precision online SPI inspection Systems, Yamaha and Seamens high speed pick-and-place machines, high precision online AOI systems and a 10 zone reflow soldering oven these ensure both high performance product outcomes and efficient production processes.

Our PCBA production process includes a dedicated DIP line, allowing for efficient and precise assembly of components using the dual in-line package (DIP) technology, ensuring high-quality and reliable circuit board assembly for our customers' electronic products.

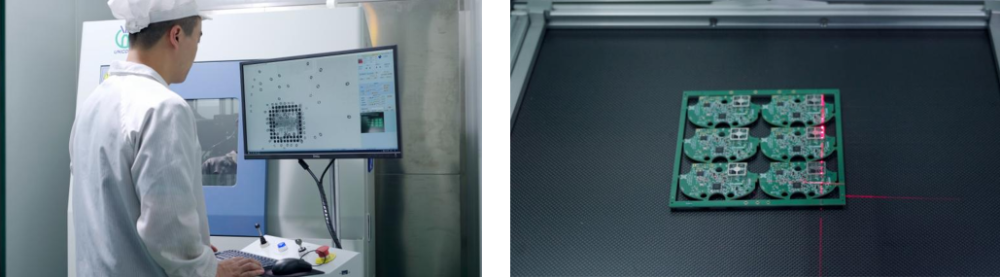

We have introduced x Ray testing equipment to detect the voiding rate of BGA solder joints analyze internal displacements of PCBA and calculate the reliability of soldering based on the test data a voiding rate and chip displacement.

Our production line also adheres to strict quality control standards to ensure that each PCBA meets customer requirements and industry standards. Our PCBA production line can not only meet the needs of large-volume orders but also flexibly handle small-volume orders, providing customers with high-quality, high-reliability PCBA products.

Welcome to contact us if any demand of PCBA requirements.